The manufacturing landscape has witnessed a remarkable transformation with the integration of automation technologies, particularly in welding operations. As industries increasingly adopt robotic welding equipment to enhance productivity and maintain consistent quality standards, the need for intelligent care solutions has become more critical than ever. Among the innovations addressing this need, WeldSaver emerges as a groundbreaking technology designed to optimise the performance and longevity of automated welding systems while significantly reducing operational costs.

Understanding the Challenge in Automated Welding

Modern manufacturing facilities rely heavily on robotic welding systems to execute precise, repeatable welds across a wide range of applications. These sophisticated machines operate continuously, performing thousands of welds daily under demanding conditions. However, this intensive operation comes with inherent challenges that can compromise efficiency and increase expenses. The primary consumable components in these systems contact tips and nozzles experience rapid wear due to the high temperatures, spatter accumulation, and mechanical stress encountered during welding processes.

Traditional approaches to managing these consumables have proven inefficient and costly. Many facilities operate on fixed replacement schedules, changing elements at predetermined intervals regardless of their actual condition. This method leads to two significant problems: premature disposal of components that still have useful life remaining, and unexpected failures when parts wear out faster than anticipated. Both scenarios result in unnecessary expenses and production disruptions that impact overall manufacturing efficiency.

The WeldSaver Innovation

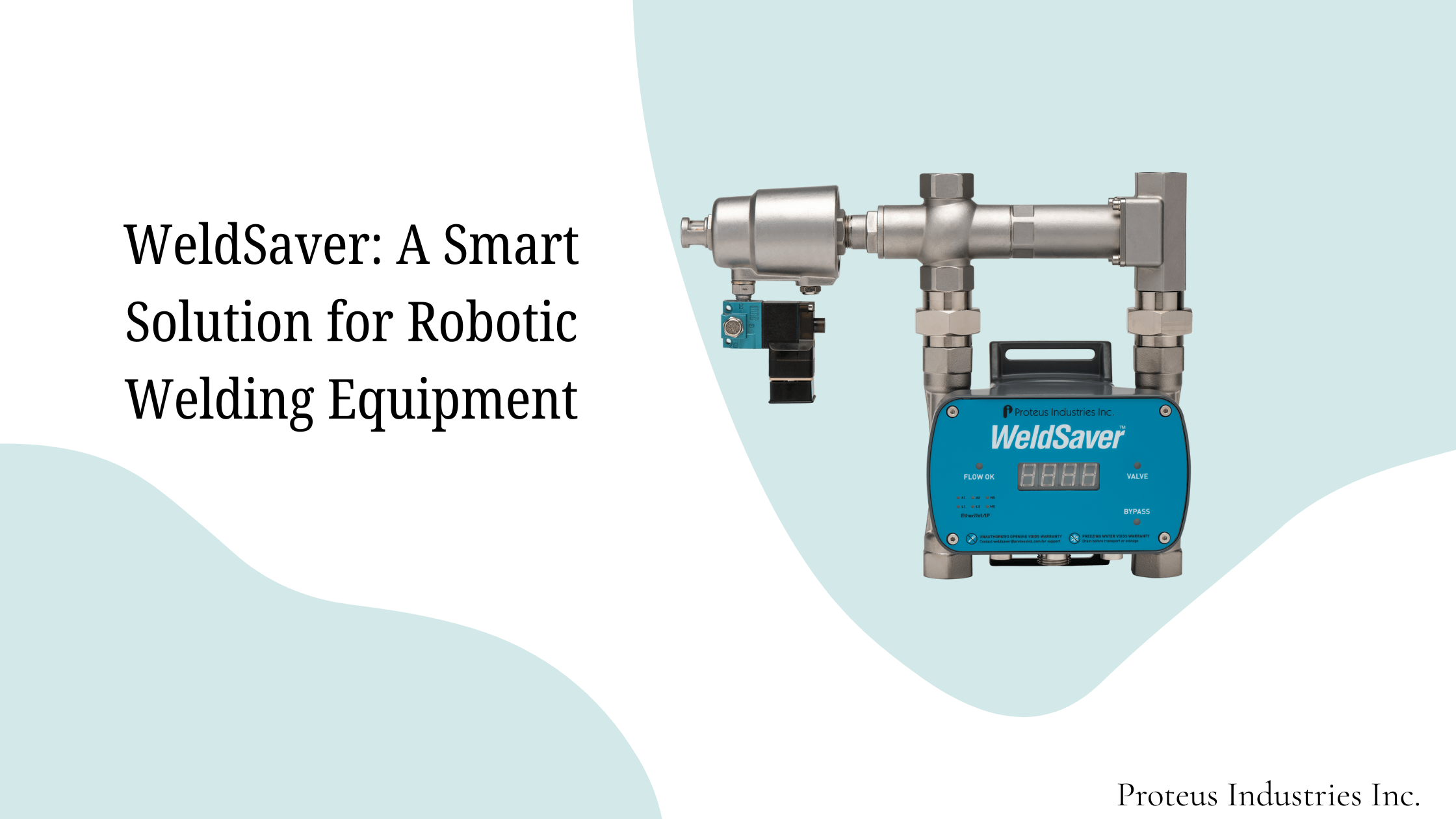

WeldSaver represents a paradigm shift in how manufacturers approach consumable management for robotic welding systems. This intelligent solution employs advanced monitoring technology to track the actual condition of welding consumables in real-time, moving beyond arbitrary schedules to condition-based maintenance. By continuously assessing component wear and performance characteristics, WeldSaver enables operators to maximise the useful life of each consumable while preventing unexpected failures that could halt production.

The system's sophisticated algorithms analyse multiple parameters throughout the welding process, including electrical characteristics, thermal patterns, and performance metrics. This comprehensive monitoring approach provides unprecedented visibility into consumable health, enabling maintenance teams to make informed decisions based on the actual condition of components, rather than relying on guesswork or conservative estimates.

Key Benefits and Operational Advantages

The implementation of WeldSaver delivers transformative benefits across multiple dimensions of manufacturing operations. Cost reduction stands as one of the most immediate and measurable advantages. By eliminating premature replacement of consumables and optimising usage patterns, facilities typically experience substantial decreases in material expenses. The system ensures that contact tips and nozzles are utilised to their full potential, extracting maximum value from each component before replacement becomes necessary.

Production uptime receives a significant boost through WeldSaver's predictive capabilities. Unexpected equipment failures and emergency maintenance interventions become rare occurrences when operators have a warning of consumable degradation. This proactive approach enables maintenance activities to be scheduled during planned downtime, minimising disruptions to production schedules and maintaining consistent output levels.

Quality consistency represents another crucial benefit delivered by this intelligent solution. As welding consumables wear, they can produce variations in weld quality that may not be immediately apparent but can compromise structural integrity or aesthetic standards. WeldSaver's monitoring capabilities detect subtle changes in performance before they translate into quality defects, ensuring that every weld meets specifications throughout the consumable's operational life.

Technical Integration and Operational Simplicity

Despite its sophisticated monitoring capabilities, WeldSaver is designed for straightforward integration into existing robotic welding systems. The technology works seamlessly with various welding equipment brands and models, eliminating the need for extensive modifications or specialised infrastructure. This compatibility ensures that facilities can adopt the solution without disrupting existing workflows or requiring significant capital investments in new equipment.

The user interface prioritises accessibility and clarity, presenting critical information through intuitive dashboards that maintenance personnel and operators can quickly understand and act upon. Alert systems notify relevant team members when consumables approach their replacement thresholds, providing adequate lead time for planning and executing maintenance activities. This streamlined communication ensures that the right people have the right information at precisely the right moment.

Environmental and Sustainability Impact

Beyond operational and financial benefits, WeldSaver makes a meaningful contribution to manufacturing sustainability objectives. By optimising consumable usage and eliminating wasteful early replacements, the system reduces the volume of metal waste generated by welding operations. This waste reduction aligns with corporate environmental goals and regulatory requirements while demonstrating responsible resource stewardship.

The extended operational life of consumables also translates to reduced packaging waste, fewer delivery shipments, and decreased energy consumption associated with manufacturing replacement parts. These cumulative environmental benefits complement cost savings, creating a compelling case for adoption from both economic and ecological perspectives.

Strategic Value for Modern Manufacturing

In today's competitive manufacturing environment, even marginal improvements in efficiency and cost structure can have a significant impact on profitability and market position. WeldSaver addresses these imperatives by transforming consumable management from a routine expense into a strategic advantage. Facilities implementing this technology gain enhanced control over their welding operations, improved predictability in maintenance planning, and measurable reductions in total cost of ownership for robotic welding systems.

The data generated by WeldSaver also provides valuable insights for continuous improvement initiatives. Historical performance information helps identify patterns, optimise welding parameters, and refine operational procedures. This analytical capability supports broader manufacturing excellence programs and contributes to organisational learning across production teams.

Conclusion

As manufacturing continues evolving toward greater automation and intelligence, solutions like WeldSaver demonstrate how targeted innovations can address specific operational challenges while delivering broad strategic benefits. By introducing intelligent monitoring and predictive capabilities to robotic welding consumable management, this technology enables facilities to maximise equipment performance, control costs, and maintain quality standards in increasingly competitive markets. The combination of immediate cost savings, operational improvements, and environmental benefits positions WeldSaver as a vital component of modern automated welding operations, delivering value that extends far beyond simple consumable tracking to encompass comprehensive optimisation of welding processes.