IMARC Group’s “Sandpaper Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” report provides a comprehensive guide on how to successfully set up a sandpaper manufacturing plant. The report offers clarifications on various aspects, such as unit operations, raw material requirements, utility supply, infrastructural needs, machinery models, labour necessities, transportation timelines, packaging costs, etc.

In addition to the operational aspects, the report also provides in-depth insights into sandpaper manufacturing plant cost, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful sandpaper manufacturing unit.

Request for a Sample Report: https://www.imarcgroup.com/sandpaper-manufacturing-plant-project-report/requestsample

What is Sandpaper?

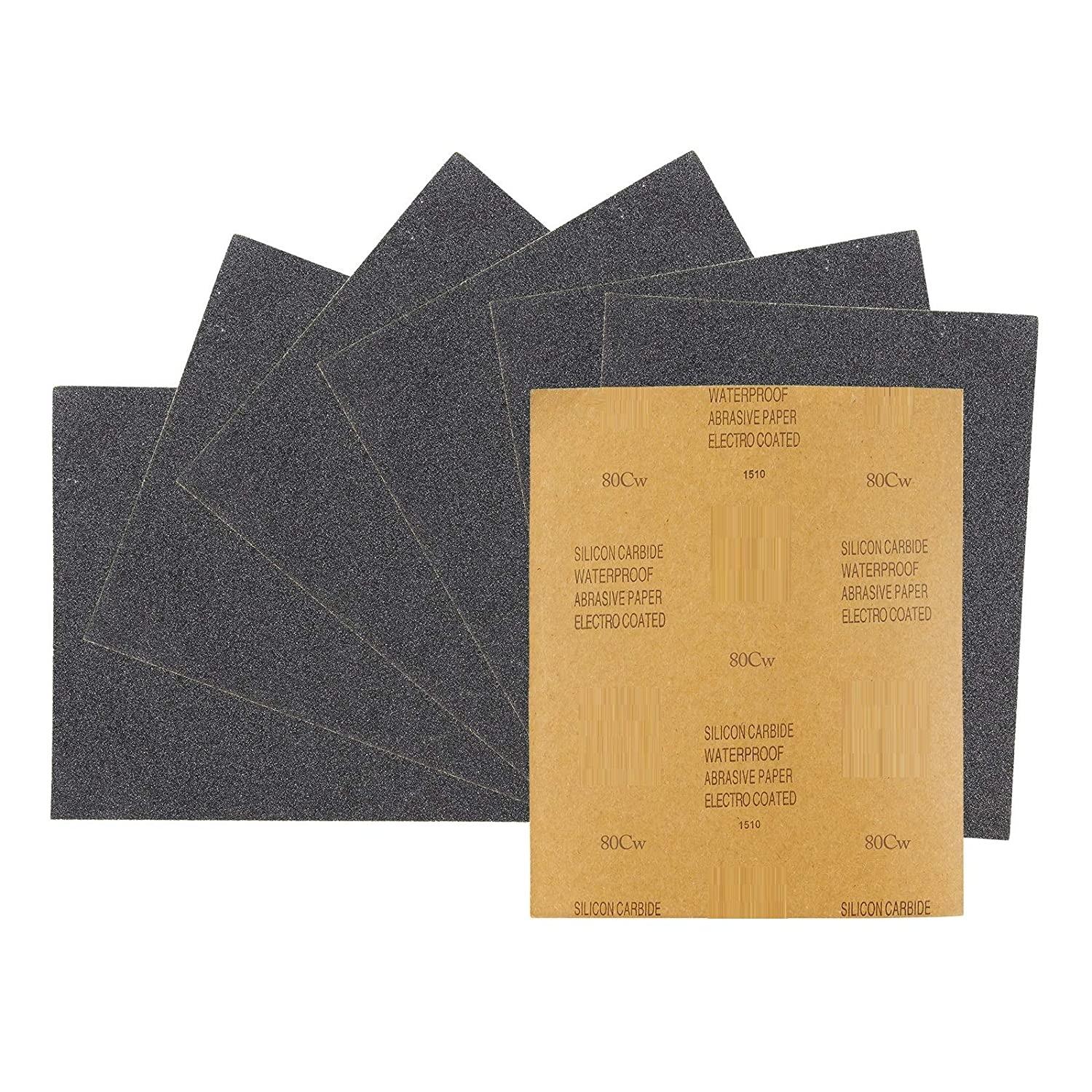

Sandpaper is a versatile abrasive material widely used for smoothing, polishing, and shaping surfaces in industries such as woodworking, metalworking, construction, and automotive repair. It consists of a sheet of paper or fabric coated with abrasive particles like aluminum oxide, silicon carbide, garnet, or ceramic, which vary in grit size depending on the intended application. Coarse-grit sandpaper is generally used for heavy material removal and surface preparation, while fine-grit sandpaper is applied for finishing and polishing to achieve smooth surfaces. Available in sheets, belts, discs, and rolls, sandpaper caters to both manual and machine-based applications. Its effectiveness lies in its ability to provide precise finishing, extend the durability of coatings, and enhance surface quality. The product is essential not only in professional manufacturing and repair processes but also in household maintenance tasks such as paint preparation, rust removal, and furniture refinishing, making it a critical consumable in various industries.

Market Trend and Drivers of Sandpaper:

The sandpaper market is witnessing steady growth, driven by rising demand from woodworking, construction, and automotive industries. Increasing global infrastructure projects and growing furniture manufacturing are fueling the need for high-quality abrasives that ensure smooth finishes and longer-lasting products. Additionally, the automotive sector heavily relies on sandpaper for surface preparation in painting, dent repair, and refinishing, further supporting market expansion. Technological advancements have led to the development of longer-lasting, eco-friendly sandpapers with advanced coatings, meeting both efficiency and sustainability requirements. The do-it-yourself (DIY) trend and rising interest in home improvement projects are also boosting consumer demand. Moreover, industrial automation and the use of sanding machines in mass production have increased the adoption of specialized sandpaper formats like belts and discs. With the shift toward premium materials and precision finishing, the market is expected to grow consistently, supported by innovation, urbanization, and expanding applications across diverse industries.

Key Aspects to Setup a Sandpaper Plant:

- Location to Setup Plant – Choose a strategic site with access to raw materials, skilled labor, and good transportation facilities.

- Market Research – Analyze demand, competition, and pricing trends to identify growth opportunities in the abrasive industry.

- Plant Layout – Design an efficient layout ensuring smooth workflow from raw material input to finished sandpaper output.

- Construction and Infrastructure – Develop adequate buildings, utilities, and storage areas to support production operations.

- Equipment/Machinery Procurement – Acquire high-quality machinery for coating, cutting, drying, and packaging sandpaper.

- Documentation and Licenses – Obtain necessary permits, environmental clearances, and industry certifications for legal operations.

- Cost Analysis – Estimate capital investment, operating expenses, and profitability to plan financial feasibility of the plant.

Requirements to Setup a Facility:

- Funds

- Machinery

- Lands

Types of Costs to Setting up a Sandpaper Factory:

- Land, Location and Site Development Cost

- Plant Layout Cost

- Machinery Requirements and Costs

- Raw Material Requirements and Costs

- Packaging Requirements and Costs

- Transportation Requirements and Costs

- Utility Requirements and Costs

- Human Resource Requirements and Costs

Project Economics:

- Capital Investments

- Operating Costs

- Expenditure Projections

- Revenue Projections

- Taxation and Depreciation

- Profit Projections

- Financial Analysis

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Services:

- Plant Setup

- Factoring Auditing

- Regulatory Approvals, and Licensing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)