Precision Finishes: Advancing Production with Industrial Coatings 2026

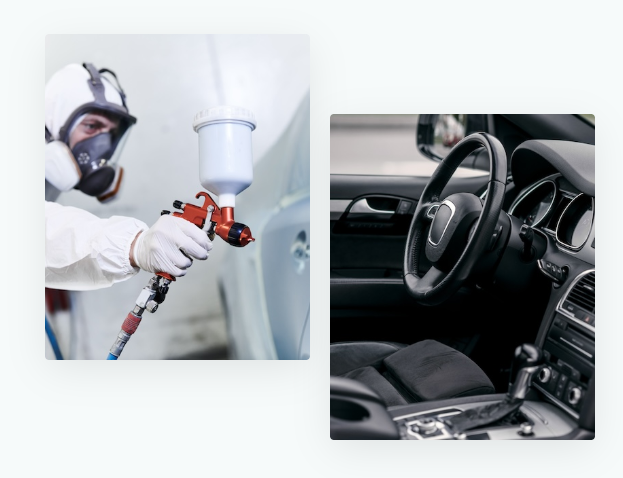

In the manufacturing landscape of 2026, the transition toward high-performance, sustainable finishes has become a core requirement for operational success. Whether you are producing high-end furniture or specialized automotive components, the choice of your finishing partner dictates both the durability of your product and the efficiency of your line. As an established industrial wood stain supplier, the focus has shifted toward bio-based formulations and low-VOC (Volatile Organic Compound) systems that meet stringent global environmental standards without compromising on the depth of color or grain clarity.

The OEM Advantage: Tailored Performance

Modern Original Equipment Manufacturers (OEMs) require more than just off-the-shelf solutions. The role of a custom coatings supplier for OEMs in 2026 is defined by a deep technical partnership. This involves developing specific formulations—ranging from UV-curable topcoats to high-heat resistant acrylics—that are precisely engineered for a manufacturer's unique application environment. These custom solutions ensure maximum adhesion, chemical resistance, and a finish that defines the brand's aesthetic.

Benefits of Custom Formulation:

- Enhanced Throughput: Quick-dry and low-bake technologies reduce downtime and energy consumption.

- Substrate Compatibility: Formulations specifically designed for new-age composites, metals, or hardwoods.

- Regulatory Readiness: Ensuring all coatings are pre-compliant with 2026 environmental and safety mandates.

- Superior Durability: Protection against UV degradation, abrasion, and harsh industrial cleaners.

Supply Chain Excellence: Beyond the Product

In a globalized economy, the "how" is just as important as the "what." A premier industrial coatings distributor serves as a vital bridge between innovation and application. In 2026, distribution has evolved into a value-added service model that includes just-in-time inventory management, virtual formulation tools, and on-site technical support to troubleshoot application challenges in real-time.

Comparison of Coating Systems in 2026:

| Coating Type | Primary Benefit | Common Application |

| Waterborne Acrylics | Low-VOC & Quick Dry | Furniture & Millwork |

| UV-Curable | Instant Drying & High Build | Flooring & High-Volume OEM |

| Polyurethane | Chemical & Impact Resistance | Cabinetry & Industrial Parts |

| Epoxy Primers | Superior Metal Adhesion | Heavy Equipment & Steel |

Sustainable Innovation for a Circular Economy

The industrial coatings sector in 2026 is heavily influenced by the circular economy. Suppliers are now prioritizing renewable resins and "smart" coatings that can self-heal or offer antimicrobial properties. For wood finishers, this means access to stains that penetrate deeper and last longer, reducing the need for frequent refinishing and lowering the overall lifecycle impact of the wood product.

Conclusion: Future-Proofing Your Finish

The year 2026 rewards manufacturers who prioritize quality at the surface level. By aligning with a partner that offers specialized wood stains, custom OEM solutions, and a robust distribution network, you ensure your products not only look superior but are built to endure the rigors of modern use.