The laser industry has been transformed in recent years by one critical component: the galvo scanner. This compact yet powerful device is the backbone of high-speed, precision-driven laser systems used across industries ranging from electronics to automotive and medical device manufacturing. With the increasing demand for faster processing speeds, smaller feature sizes, and higher reliability, the global market is pushing galvo scanner manufacturers to innovate. Laserchina, a trusted name in advanced laser solutions, has consistently stayed ahead of these market requirements with state-of-the-art galvo scanner technology.

Market Demands Driving Galvo Scanner Development

In today’s competitive industrial environment, customers demand equipment that can deliver three key outcomes: speed, accuracy, and reliability. Galvo scanners are central to achieving these goals because they control the position of laser beams with incredible precision.

-

Speed Requirements: Manufacturers need equipment capable of handling mass production without compromising accuracy. Galvo scanners allow laser beams to be directed at extremely high speeds, which increases throughput and lowers operational costs.

-

Precision Standards: As industries like semiconductors and electronics shrink their component sizes, there is no tolerance for error. The galvo scanner must maintain consistent beam positioning at micro-scale levels.

-

Durability and Reliability: Companies are unwilling to risk downtime. Galvo scanners must be designed with long service life and minimal maintenance, even under continuous operation.

Laserchina has positioned its galvo scanners to meet these demands head-on, ensuring their products remain at the forefront of market expectations.

Laserchina’s Latest Galvo Scanner Innovations

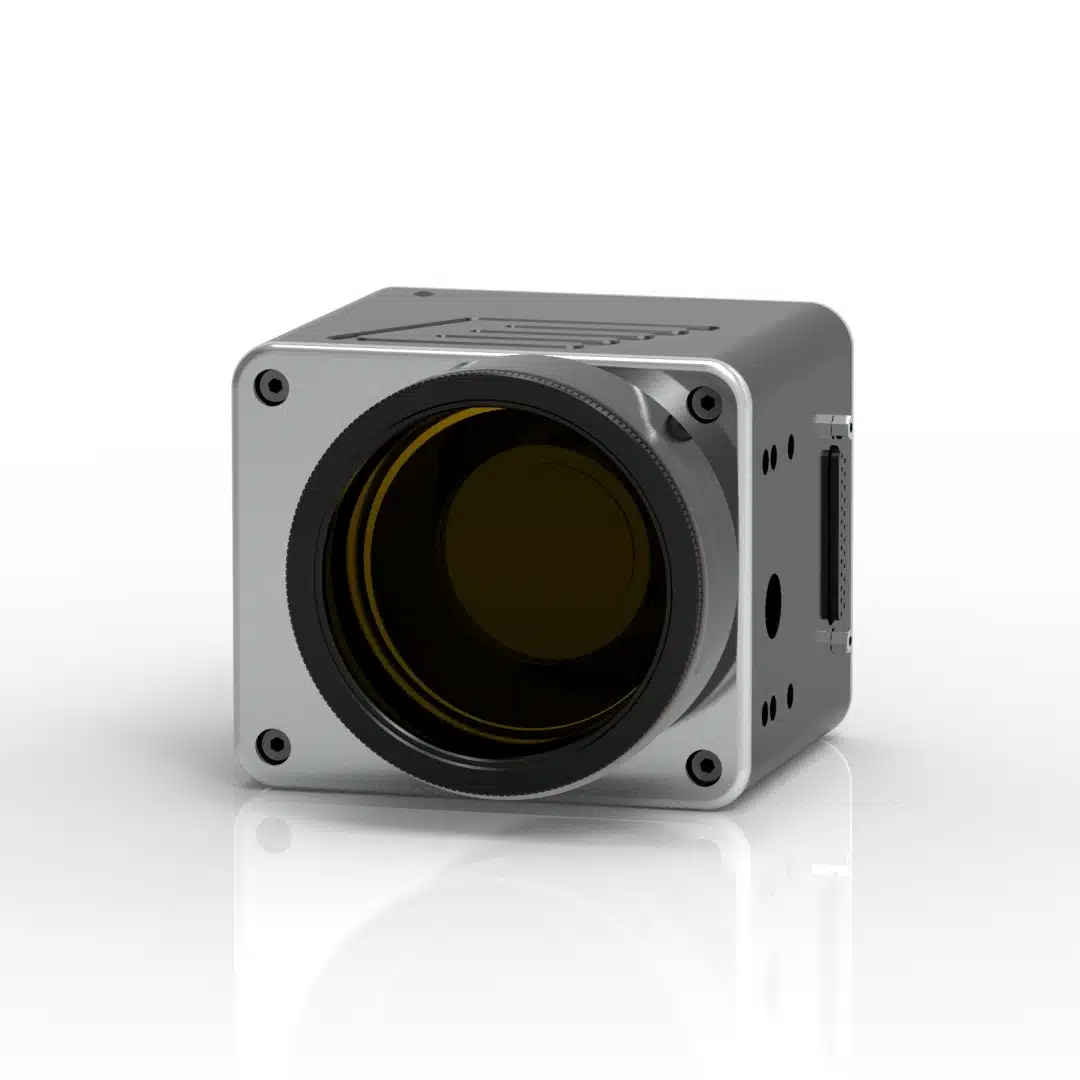

Laserchina’s galvo scanners are engineered with advanced mirror technology, high-torque motors, and precision feedback control systems. These features ensure that each scanner not only meets but exceeds the growing demands of modern industries.

-

High-Speed Scanning: Laserchina integrates lightweight, coated mirrors with optimized designs to maximize scanning velocity without sacrificing stability. This is crucial for industries where even a few seconds of cycle time reduction can result in major cost savings.

-

Micro-Precision Control: The company uses advanced digital control systems with closed-loop feedback. This allows laser beams to be positioned with micrometer-level accuracy, ensuring consistent quality across every production run.

-

Thermal Stability: One of the hidden challenges in galvo scanners is heat generation during continuous use. Laserchina applies advanced cooling and material innovations to ensure stable performance even under heavy-duty conditions.

Meeting International Standards and Industry Requirements

Global industries are not only demanding faster and more accurate systems but also compliance with international standards for safety and performance. Laserchina ensures every galvo scanner aligns with ISO certifications and CE standards. This commitment to quality control provides customers with confidence that they are investing in equipment that performs reliably and consistently under international benchmarks.

Moreover, Laserchina actively collaborates with industry partners to anticipate emerging requirements. For example, as additive manufacturing expands, the demand for galvo scanners capable of handling three-dimensional beam shaping is rising. Laserchina has already incorporated 3D scanning systems into its product line to serve this growing sector.

Customer-Centric Solutions from Laserchina

One of the strengths of Laserchina is its ability to tailor solutions to specific customer needs. Instead of offering generic products, the company works closely with clients to optimize galvo scanners for particular applications—whether that’s engraving fine jewelry, cutting intricate electronic circuits, or marking medical devices with high precision.

This customer-centric approach ensures that buyers do not just receive a product but a complete solution that enhances their production efficiency and competitiveness.

Why Choose Laserchina Galvo Scanners?

-

Proven Expertise: Decades of experience in the laser industry, giving Laserchina a deep understanding of both technology and market trends.

-

Cutting-Edge Technology: Continuous investment in R&D to develop galvo scanners that set new performance benchmarks.

-

Global Reliability: Compliance with international standards and extensive customer support worldwide.

-

Application Versatility: From large-scale industrial production to highly specialized precision marking, Laserchina’s galvo scanners deliver across sectors.

Conclusion

As industries move toward faster production cycles, miniaturization of components, and uncompromising quality, the galvo scanner has become a vital component in laser systems. Market demands for speed, accuracy, and durability are reshaping how manufacturers design and deploy these scanners. Laserchina has embraced these challenges by developing advanced galvo scanners that not only meet today’s requirements but also anticipate tomorrow’s needs. For businesses seeking precision, reliability, and scalability, Laserchina’s galvo scanners represent a proven solution that ensures long-term success in a competitive market.